[Micro▪Interview] TMR Central Kitchen Feeding System of Youmu Machinery

Release time:

Sep 18,2024

Over the years, Youmu Machinery has developed a series of new products according to its development needs.

Youmu Machinery TMR Central Kitchen Feeding System-High Efficiency, Cost Reduction and Efficiency Increase

At present, the dairy industry is experiencing a downturn in the industry, with stagnant consumption, overproduction of milk, intensifying the contradiction between supply and demand in the dairy industry, and the development of the dairy industry is facing unprecedented challenges.

In recent years, the TMR central kitchen automatic feeding system has changed the traditional feeding mode, and has been generally recognized by the industry in terms of processing efficiency, reducing energy consumption, and reducing labor, and has truly achieved quality improvement, cost reduction and efficiency increase. Especially during the current downturn in the dairy industry, pastures are trying to reduce costs and production capacity.

Since 2016, Hebei youmu machinery manufacturing co., ltd. has explored, designed and developed the TMR central kitchen automatic feeding system on the basis of raising cattle in its own pasture. in 2019, it has successfully operated the TMR central intelligent kitchen system in its own pasture. Over the years, Youmu Machinery has developed a series of new products according to its development needs.

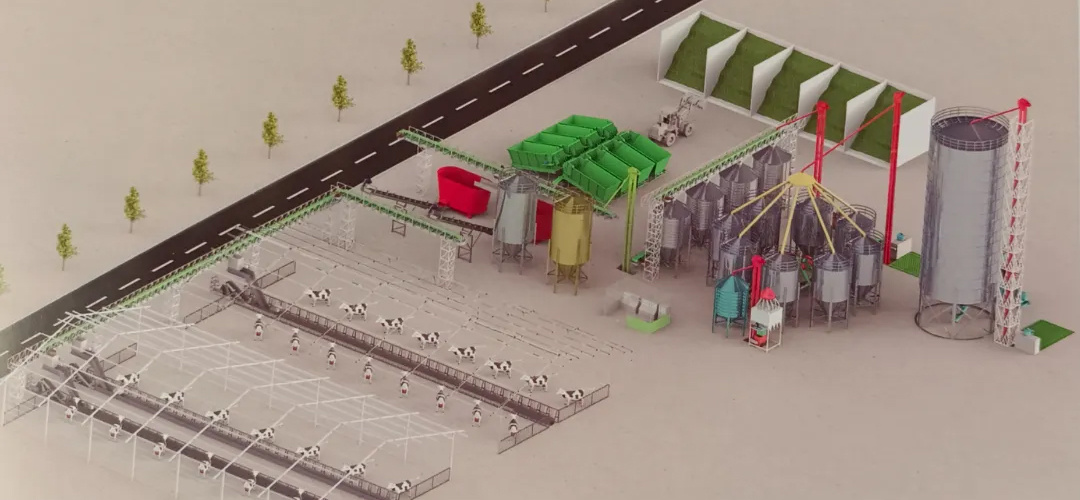

The TMR central kitchen automatic feeding system independently developed by Youmu Machinery is controlled by a computer. Several powder silo groups, hay silo groups and liquid silo groups are formed. Various raw materials are automatically added to the TMR in a proportional order, stirred regularly and fed quantitatively. The mixed feed is automatically and quantitatively transported to the cattle trough by the conveying system, and the remaining grass is automatically collected regularly and uploaded to the system, in order to adjust the amount of diet in a timely manner. It is a revolutionary innovation in the feeding process of cattle farms to fully realize automatic control such as automatic mixing, timing mixing and quantitative discharging, effectively realize accurate feeding of TMR in cattle farms, with an error rate of less than 1%, and maximize the consistency of TMR mixing quality, save labor and labor, and liberate TMR operators from heavy manual labor.

This system from the input formula to the quantitative ingredients, timing mixing, quantitative discharge, fully automated. PLC man-machine interface, humanized design, remote control, warehouse management, so that the error loss of the cattle farm to a minimum, every year to reduce a lot of expenditure for the pasture, so that the feeding system to achieve unmanned management, greatly improve the efficiency of pasture management, is the future development direction of wisdom pasture.

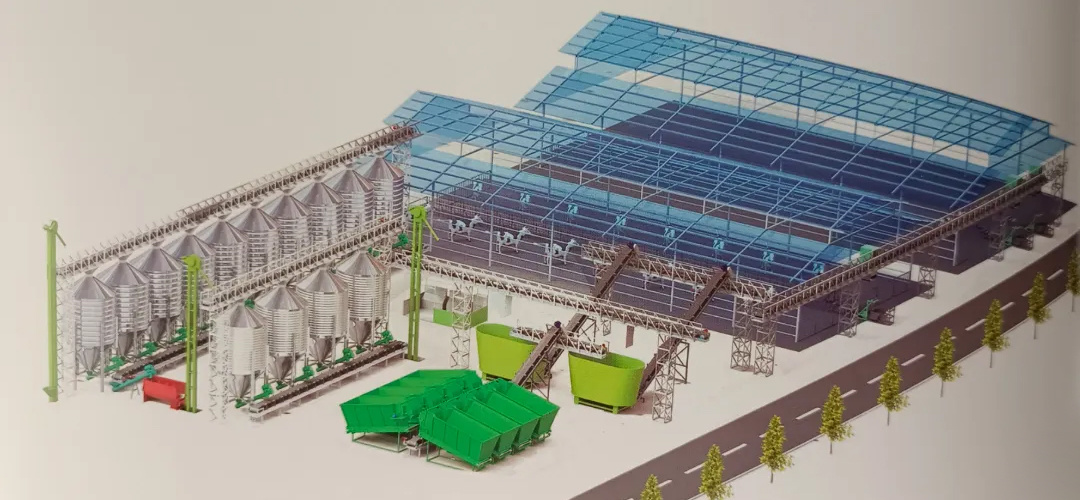

Excellent Animal Husbandry Machinery: Inner Mongolia Tuojian TMR Total Mixed Fermentation Ration Project

The TMR full mixed fermentation ration project of Inner Mongolia Tuojian Nong Animal Husbandry Technology Co., Ltd. built by Hebei Youmu Machinery has been operating normally. Inner Mongolia Tuojian Nong Animal Husbandry Technology Co., Ltd. has a full automatic production line with an annual output of 50000 tons of ruminant feed, a TMR full mixed fermentation ration production line and a 15000 mu pasture planting base, providing camel farmers with high-quality camel forage and refined feed.

Tuojian farming and animal husbandry TMR full mixed fermentation diet project includes central control system, silage automatic retrieval and transportation system, hay pretreatment system, concentrate storage and addition system, roughage storage and addition system, stirring and mixing system, finished material storage and discharge system and wrapping system.

The full-automatic recharging system realizes automatic advancement, automatic quantitative recharging, saving fuel and labor, and the silage is transported to the silage silo by belt.

For alfalfa, oat, Leymus chinensis and other bales of different packaging and sizes, Youmu Machinery has different equipment to automatically unpack and peel, and then the hay after shredding and dust removal is transported to the hay bin by belt.

Different forage materials transported to the grass silo are stored in different grass storage. According to different production requirements, the silo is automatically weighed and discharging according to the set proportion. The forage materials are transported to the TMR mixer by belt, and then refined materials, molasses, bacterial liquid, etc. are added for stirring.

The mixed feed is automatically discharging and transported to the temporary storage warehouse. According to different production requirements, full mixed fermented ration wrapping products with different packaging specifications can be produced.

Each section of automatic feeding system for central kitchen of Youmu Machinery TMR

The TMR central kitchen automatic feeding system independently developed by Hebei Youmu is composed of different sections. The pasture can choose some section equipment or all section equipment according to its own situation.

→ Fully automatic silage taking into warehouse section:The silage automatic silage feeding system is installed in the silage cellar. The cantilever type automatic grass picking device. When the TMR workshop needs it, the central control will issue an instruction, and the grass picking device will be automatically opened, and the silage will be automatically added to the temporary storage bin through the transmission device through the automatic weighing system for standby.

→ Fully automatic hay unloading and palletizing section:The grass can be automatically unloaded and palletized to the designated area for storage, and the stock grass can also be automatically stacked on the hay conveyor chain.

→ Fully automatic hay removal, rope removal, foreskin removal, scattering and crushing into warehouse section:The full-automatic hay rope removing and wrapping machine is a new product developed by Youmu. The hay processing device is that workers place the hay bales on the hay conveying chain in advance. When the hay pre-storage warehouse is short of materials, the conveying chain automatically conveys the hay to the rope removing and wrapping machine, and the hay is transported to the shredder. The shredder operates at low speed and high torque to pretreat the hay into basically qualified shredder, transporting to the temporary storage bin through the conveying device.

→ Fully automatic wrapping silage to remove foreskin and break up into warehouse section:The wrapped silage can be automatically unwrapped and scattered into a coarse silo. The wrapped silage unpacking machine is a new product developed by Youmu Machinery. First, the wrapped silage is placed on the conveying chain. The machine automatically de-films the wrapped silage and transports the wrapped silage to the temporary storage warehouse. The waste foreskin is automatically transported to the appropriate position, which effectively solves the trouble of manual foreskin removal. The whole process is automated and the efficiency is high.

→ Full-automatic roughage silo, liquid silo into TMR section:The raw materials in various coarse silo and liquid silo can be automatically added to TMR in sequence and weight

→ TMR central kitchen premix, full price self-batching section:1‰ pre-mixed raw materials can be used to form a 5% premix, and then automatically mix other raw materials to form a full-price material for use.

→ TMR Central Kitchen Whole Ration Preparation Section:According to the instructions issued by the terminal, all kinds of raw materials are automatically added into TMR according to the formula sequence, and are regularly stirred, automatically released into the temporary storage bin or pulled away by the scattering truck.

→ TMR full ration temporary storage, transportation, feeding and leftover grass recovery section: the cattle shed automatically sends out the demand, and the temporary storage warehouse automatically delivers the ration in the warehouse to the cattle trough through the transportation mechanism according to the needs of the cattle shed, and the leftover grass is automatically recovered and weighed before the next cattle feeding and uploaded the leftover material data

→ Cloud platform data control center, video surveillance:Each section is freely networked, the control center can realize unmanned operation, the mobile phone terminal can be remotely controlled upon authorization, and the whole feeding process can automatically capture data storage through the cloud platform processing center, automatically analyze, and extract and generate reports at any time.

Premix Section

The system is composed of 12 kinds of raw material warehouses, which are controlled by a computer, accurately proportioned, and automatically mixed and output premix equipment. The equipment can use 1‰ premixes to mix 5% premix, and the cost is about 2000.00 yuan per ton. The 5% premix purchased on the market is about 6000.00 yuan, and the difference per ton is between 3000.00 yuan and 4000.00 yuan.

Full-price material mixing preparation system

The full-price material mixing and preparation system consists of a batching bin group consisting of several raw material towers or conjoined material towers. The hoist stores various raw materials in the material tower, and automatically adds various raw materials to the weighing bin according to the set formula. After completion, the air gate will automatically open and put into the mixer. The mixer will automatically start mixing. After the mixing is uniform according to the time set by the system, the mixer gate will automatically open, hoist to the finished product for temporary storage.

TMR AUTOMATIC ADD SYSTEM

TMR automatic batching control system, the system is controlled by a computer, several powder silo groups, hay silo groups and liquid silo groups, automatically add all kinds of raw materials to TMR in a proportional order, regularly stir, quantitatively discharge, and store the mixed ration in a temporary storage warehouse. It is a revolutionary innovation in the feeding process of cattle farm to save labor and liberate TMR operators from heavy manual labor.

TMR precision feeding system

Breakthroughs in TMR Diet Management-Programmed, Mechanized, Automated

1. The hardware system is simple and the maintenance cost is low;

2. Based on 4G, without fear of lightning;

3. Real-time communication, high data density;

More accurate data;

5. Building house identification, accurate feeding;

6. Left grass automatic recycling, weighing, upload system

6. Auto-out, calculate the cost.

automatic feeding system

It is installed in a single-row or double-row feeding tank in the cattle house, and a conveyor belt and driving system are arranged in the tank. When cattle need to be fed, the conveyor belt conveying part signals to the central control room, which gives instructions to the temporary storage warehouse according to the demand of the cattle house, and the temporary storage warehouse automatically transfers the mixed ration to the cattle trough through the conveying mechanism through weighing.

Youmu Machinery TMR Central Kitchen Automatic Feeding System Advantage

The automatic feeding system of TMR central kitchen of excellent animal husbandry machinery has the advantages of fast processing efficiency, accurate feeding, time saving, labor saving and so on.

Nutritional balance, precision feeding

The central kitchen fully realizes automatic addition according to the process. The mixing time of various materials is adjustable, the adding amount is accurate, and the mixing is timed. Automatic facilities such as visual automatic comparison system and automatic Binzhou screen are optional. After completion, the warehouse door is automatically opened, and the mixed ration is stored in the temporary storage warehouse in time to prevent the phenomenon of excessive fine ration caused by untimely feeding, and to ensure the qualified rate of ration to the maximum extent. TMR is optional automatic grass throwing function, to prevent the phenomenon of surplus material in TMR, to prevent the secondary fermentation of surplus material in summer, to achieve balanced nutrition, consistent quality, accurate feeding and healthy breeding.

Increase yield and increase efficiency

The use of the central kitchen's self-prepared full-price materials is genuine, coupled with the precise addition of various forages, and the error rate is controlled within 1%. Cows eat a balanced diet every day, which is basically the same as the formula given by nutritionists. In this way, each cow can increase the yield by 1kg on average. According to the pasture of 5000 cows, 2500 lactating cows and 1kg of milk a day, 2500kg/day will be calculated at 3.3 yuan, it can earn nearly 10,000 yuan a day and about 300 million yuan a year.

Reducing costs and increasing revenue

According to 5000 cows, the premix consumes about 560 tons a year, and the difference between the premix produced by oneself and the premix on the market is calculated by 3000 yuan per ton, saving 560*3000=1.68 million a year.

5000 large-scale cattle farms can consume about 30 tons of full-price materials a day, saving 300 yuan per ton of materials and 30*365*300=3.28 million a year.

The total annual feed cost savings are about 5 million yuan.

Save fuel costs and reduce labor costs.

After adopting the central kitchen and automatic feeding system, the stirred ration is automatically transmitted to the cattle trough through the conveying system, thus eliminating the links of spreading truck and feeding workers pushing grass and clearing the trough. The annual oil and vehicle costs can be saved by about 1 million yuan, more than 5 TMR and feeding workers can be saved, and the annual savings can be saved (5 people * 4000 yuan/month * 12=240000), totaling 1.24 million yuan.

Reduce pasture elimination rate

After the application of the central kitchen and automatic feeding system in the pasture, the nutrition is balanced, the cows are in good condition, the lactation performance is significantly improved, the reproductive efficiency is increased, the occurrence of diseases is reduced, and the elimination rate is effectively reduced by more than 3%.

You Can Also Learn More About The Industry.

![[Micro▪Interview] TMR Central Kitchen Feeding System of Youmu Machinery [Micro▪Interview] TMR Central Kitchen Feeding System of Youmu Machinery](https://omo-oss-image.thefastimg.com/portal-saas/pg2024080919323399144/cms/image/2bc472a1-ae36-4566-87af-01a48769a55c.jpg)

![[Micro▪Good News] Hebei Youmu TMR Automatic Batching and Feeding Complete Equipment Research and Development Project Successfully Passage Acceptance [Micro▪Good News] Hebei Youmu TMR Automatic Batching and Feeding Complete Equipment Research and Development Project Successfully Passage Acceptance](https://omo-oss-image.thefastimg.com/portal-saas/pg2024080919323399144/cms/image/a1cc5d6d-e04d-4fe8-8300-5a7d45921c9a.jpg)