[Micro▪Good News] Hebei Youmu TMR Automatic Batching and Feeding Complete Equipment Research and Development Project Successfully Passage Acceptance

Release time:

Sep 18,2024

It solves the key links of standardized dairy farming, reducing feeding costs, improving feed utilization and environmental control.

At present, the survival of dairy farms has reached the era of careful calculation, the era of meager profit must let dairy farms start from bit by bit, and how to control the maximum cost of dairy farms is the most scientific solution? That is precision feeding, precision nutrition, saving costs and increasing efficiency.

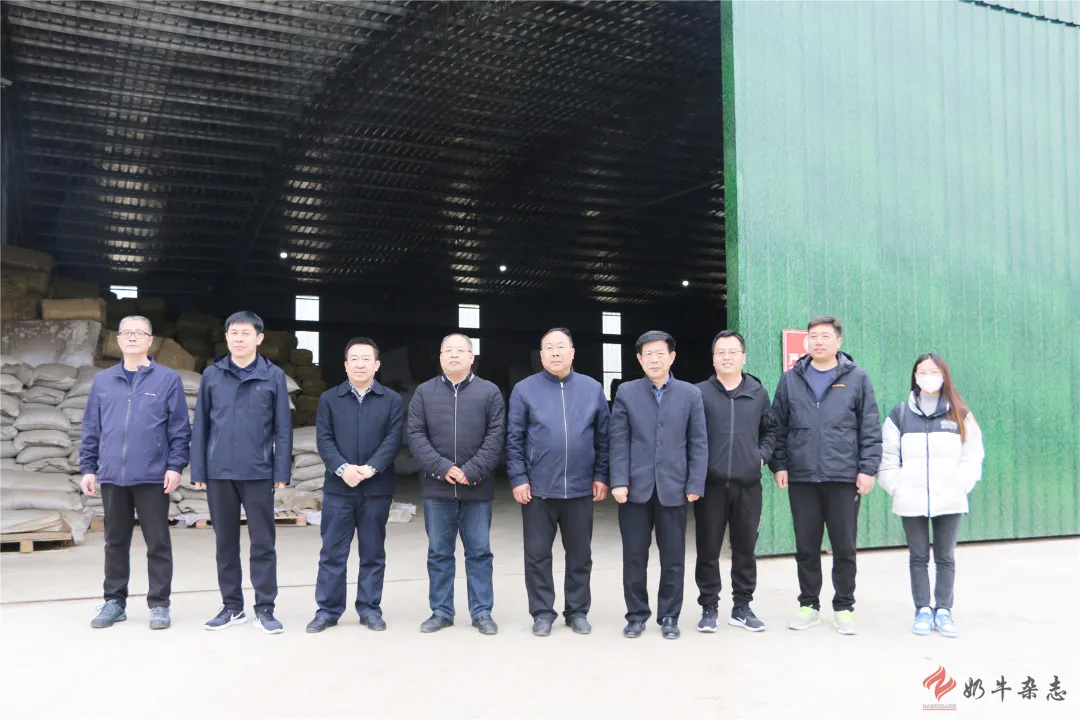

On March 17, 2022, the first prototype of Hebei youmu TMR automatic batching and feeding complete set of equipment passed the acceptance smoothly in wangyuan cattle farm in Xingtang county.

Experts attending the acceptance of the project include Fan Guochang, director and researcher of Hebei Agricultural Mechanization Research Institute, Feng Zuolong, senior engineer of Hebei Agricultural Mechanization Technology Extension Station, Zhang Zenghui, senior engineer of Shijiazhuang Agricultural Mechanization Extension Station, Yuan Ruijiang, director and researcher of Shijiazhuang Agricultural Machinery Safety Supervision Institute, Xing Yaoyao, auditor and accountant of Shijiazhuang Yongxin Certified Public Accountants. Leaders and guests attending the acceptance of the project are Jiang Guie, researcher of Hebei Animal Husbandry General Station, jia Beizhan, director of agricultural machinery in Xingtang County, Zhang Juan and Ren Shenghui, deputy directors, Luo Xubin, head and engineer of agricultural machinery extension station, Zhang Guoshuan, general manager of Hebei Youmu Machinery Manufacturing Co., Ltd., and Jin Xiaoke, engineer of Hebei Youmu Machinery Manufacturing Co., Ltd.

The research and development project of new agricultural machinery and new technology in Hebei Province was declared by Hebei Yumu Machinery Manufacturing Co., Ltd. assisted by Hebei dairy cow production performance comprehensive test station, and was officially launched in April 2020. After two years of research and development, debugging, improvement and improvement, under the guidance of experts from Hebei dairy innovation team, with the support of municipal and county agricultural machinery competent departments, and with the unremitting efforts of the research and development team, draw a satisfactory full stop.

TMR automatic batching control system is to achieve the maximum cost control to the lowest cattle farm and research and development. It solves the key links of standardized dairy farming, reducing feeding costs, improving feed utilization and environmental control. The goal of healthy, efficient and low-carbon production of dairy cows was achieved.

The equipment consists of TMR mixing bin, several powder bins, hay bins and liquid bins to form a raw material bin group. Through the linkage of hardware equipment such as automatic control, automatic transmission, automatic weighing, automatic mixing and automatic feeding, the equipment is integrated with software control and intelligent control equipment.

Through the control console, the cloud platform dairy cow diet nutrition formula is sent out, the control module installed on the TMR receives the instructions sent by the system, and the sensor controls the accurate addition and regular mixing of various material silos, and the mixed feed that meets the quality is quantitatively fed according to the requirements of the cattle shed. The recovery equipment and system track the situation of overfeeding and leftover material, summarize and analyze the individual feeding data of dairy cows, so as to dynamically track the results of formula implementation, and provide a reliable basis for formula effectiveness analysis on the basis of accumulated data.

innovation point

1. A complete set of automation equipment that integrates hardware design and production with software development.

2. The development of complete sets of equipment for total mixed ration is integrated with the automatic addition and recycling equipment of cattle sheds.

3. Automated and precise feeding, which can track data accuracy and effectiveness.

TMR automatic batching and feeding equipment research and development system has a high level of automation. It uses automation technology, batching equipment, conveying equipment, feeding equipment, recycling equipment and other parts to realize fully automated operation, avoiding a lot of manual duplication of work and reducing labor intensity. The information capability is perfect. The system uses fieldbus technology to manage all equipment in a unified way. Managers can realize the whole process management through computers, mobile phones and other terminals, and the information transmission is efficient and fast. Increase the dry matter intake of dairy cows and improve the efficiency of feed conversion. The system is designed with user-defined functions such as independent batching, which allows users to make production arrangements in full accordance with the actual situation, with strong autonomy. Meet the daily feeding management requirements of dairy farms.

Analysis of economic and social ecological benefits

1. reduce feed costs.

After the equipment is completed, the cost of feed per ton can be reduced by about 500 yuan per ton compared with the feed of the feed factory. According to the calculation of 1000 cattle farms, the daily use of concentrate is about 4.5 tons, 365 days a year, saving 500 yuan per ton and 820000 yuan per year.

2. increase milk production.

Since the ingredients are real things, coupled with the precise addition of various forage materials, the error rate is greatly reduced, and there is basically no difference between the feed that cows eat in their mouths and the formula produced by nutritionists, so that each cow can increase the yield by at least one kilogram per day. According to the calculation of 500 lactating cows, the milk yield can be increased by 500 kilograms per day, and the income can be increased by more than 730000 yuan per year.

3. reduce the amount of remaining grass.

In the feeding process, the remaining forage can be controlled within 1%-2%. According to the calculation that each cow can save 2% of the feed every day, the prepared total ration is 1500 yuan/ton, and the 1000-head cattle farm can save the remaining forage cost about 180000 yuan a year.

4. reduce labor input costs.

The labor intensity of TMR workers is reduced, and 2 TMR workers and 3 cattle feeders can be saved, with a total cost of 210000 yuan (5 people 3500 yuan/month * 12=210000).

5. reduce the elimination rate of cows.

Dairy cows feed well and eat well can reduce the elimination rate of dairy cows by 3%. According to the calculation of 1000 cattle farms, 30 cows are panned less in a year. According to the calculation of 20000 yuan per cow, 600000 yuan can be reduced in a year. To sum up, the use of TMR automatic batching control system to raise cattle can save at least more than 250 million yuan a year. The equipment cost of 1000 dairy farms is about 4 million, and the equipment cost investment can be recovered in less than 2 years.

social benefit

The equipment has the function of automatically controlling the recovery of leftover materials, which can collect the leftover materials regularly and automatically weigh them, and estimate the amount of leftover materials in each cattle house and automatically upload it to the platform, so that nutritionists can adjust the formula and delivery ratio in time, so as to achieve timing and accurate delivery, accurate feeding, accurate recovery, accurate nutrition, reduce unnecessary waste of feed, maximize pasture benefits, and make dairy farms intensive and automatic, the development of modernization has laid a solid technical foundation and has extensive and significant demonstration-driven benefits. The purpose of saving cost and increasing efficiency for the farm is achieved.

You Can Also Learn More About The Industry.

![[Micro▪Interview] TMR Central Kitchen Feeding System of Youmu Machinery [Micro▪Interview] TMR Central Kitchen Feeding System of Youmu Machinery](https://omo-oss-image.thefastimg.com/portal-saas/pg2024080919323399144/cms/image/2bc472a1-ae36-4566-87af-01a48769a55c.jpg)

![[Micro▪Good News] Hebei Youmu TMR Automatic Batching and Feeding Complete Equipment Research and Development Project Successfully Passage Acceptance [Micro▪Good News] Hebei Youmu TMR Automatic Batching and Feeding Complete Equipment Research and Development Project Successfully Passage Acceptance](https://omo-oss-image.thefastimg.com/portal-saas/pg2024080919323399144/cms/image/a1cc5d6d-e04d-4fe8-8300-5a7d45921c9a.jpg)